Valsteam ADCA

Спецификации

-

Function

Designed to ensure highly efficient and moisture free steam injection in air ducts and AHU for humidification purposes.

-

Application

Saturated steam

-

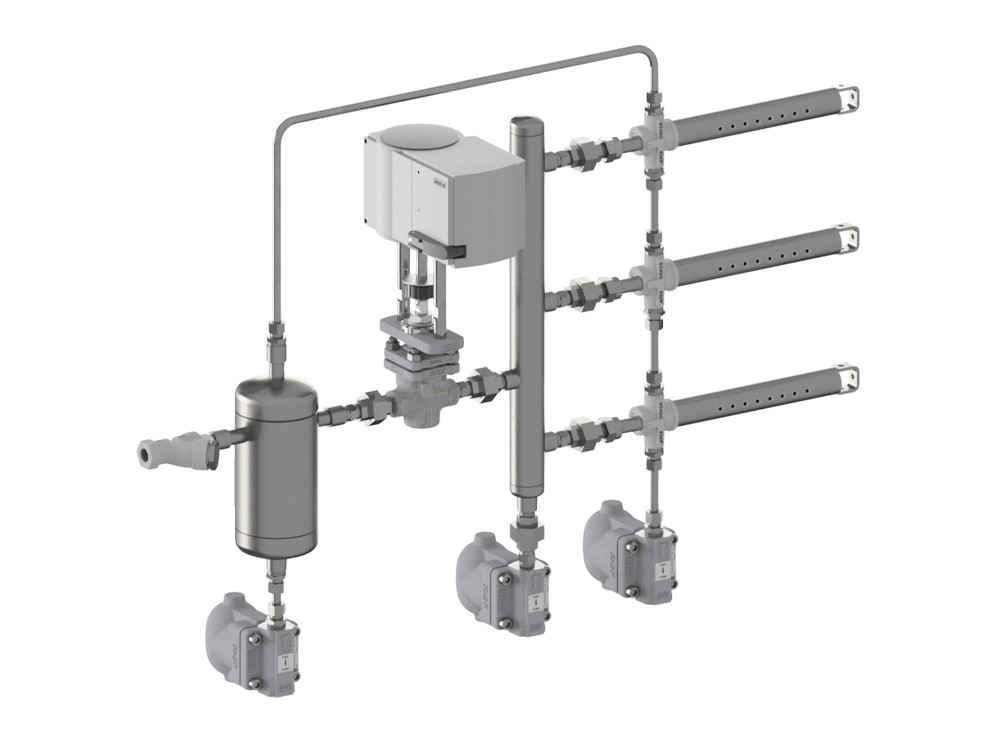

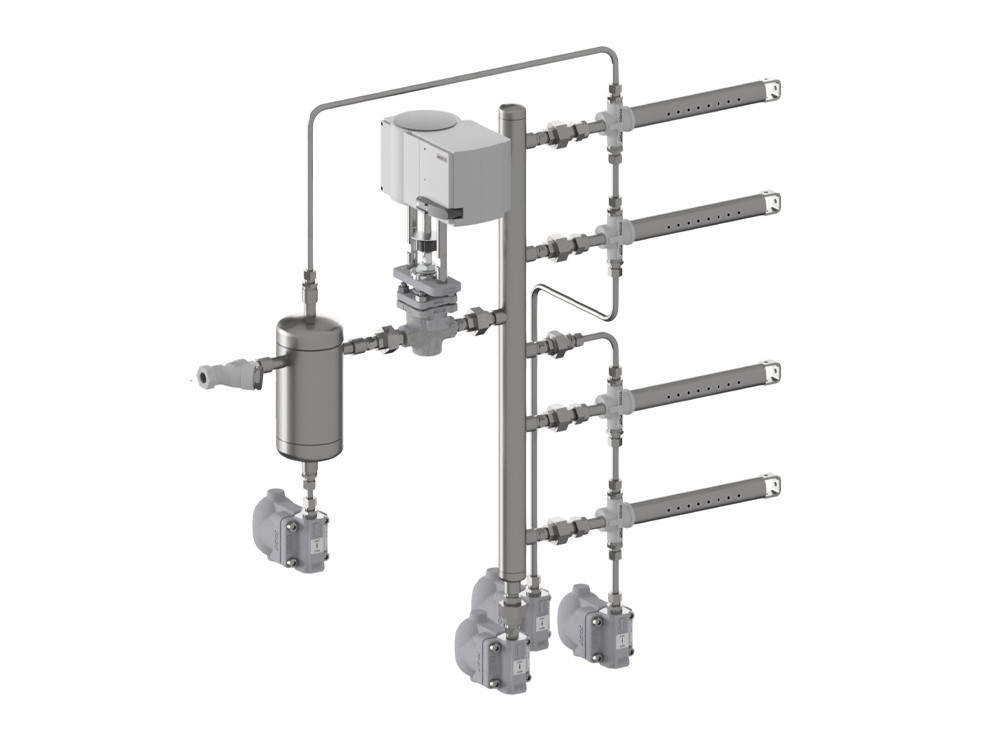

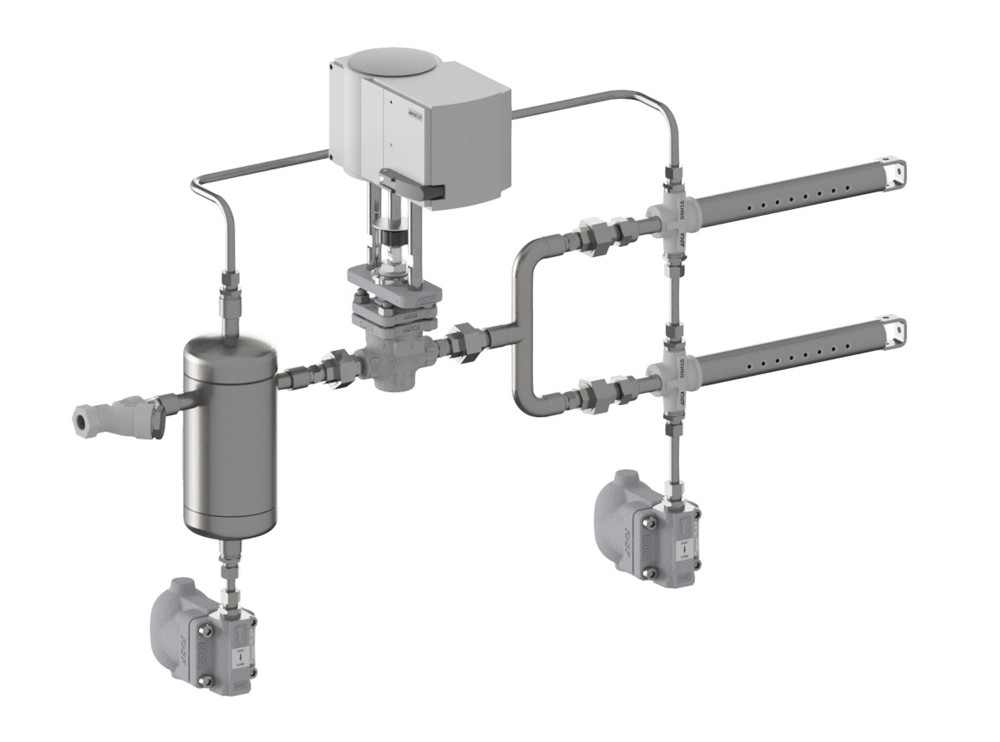

Number of tubes

2 injection tubes,

3 injection tubes,

4 injection tubes,

5 or more injection tubes -

Material

Full stainless steel construction

-

Max. allowable pressure

Tube humidifier – 12 bar (PN 16),

Injection tube – 4 bar (PN 6) -

Max. allowable temperature

Tube humidifier – 250 ºC,

Injection tube – 152 ºC -

Max. humidification load

DSH10 – up to 233 kg/h,

DSH25 – up to 645 kg/h,

DSH30 – up to 1079 kg/h -

Insertion length

DSH10 – Min.: 180 / Max.: ≥ 1001 mm,

DSH25 – Min.: 330 / Max.: ≥ 1251 mm,

DSH30 – Min.: 980 / Max.: ≥ 1551 mm -

Max. duct height

2 of tubes – up to 1500 mm,

3 of tubes – 1501 – 2000 mm,

4 of tubes – 2001 – 2500 mm,

5 or more tubes – above 2501 mm -

Connections

Female threaded ISO 7 Rp (NPT on request) PN16,

Flanged EN 1092-1 PN 16,

Flanged ASME B16.5 Class 150 on request