Valsteam ADCA

Специфікація

-

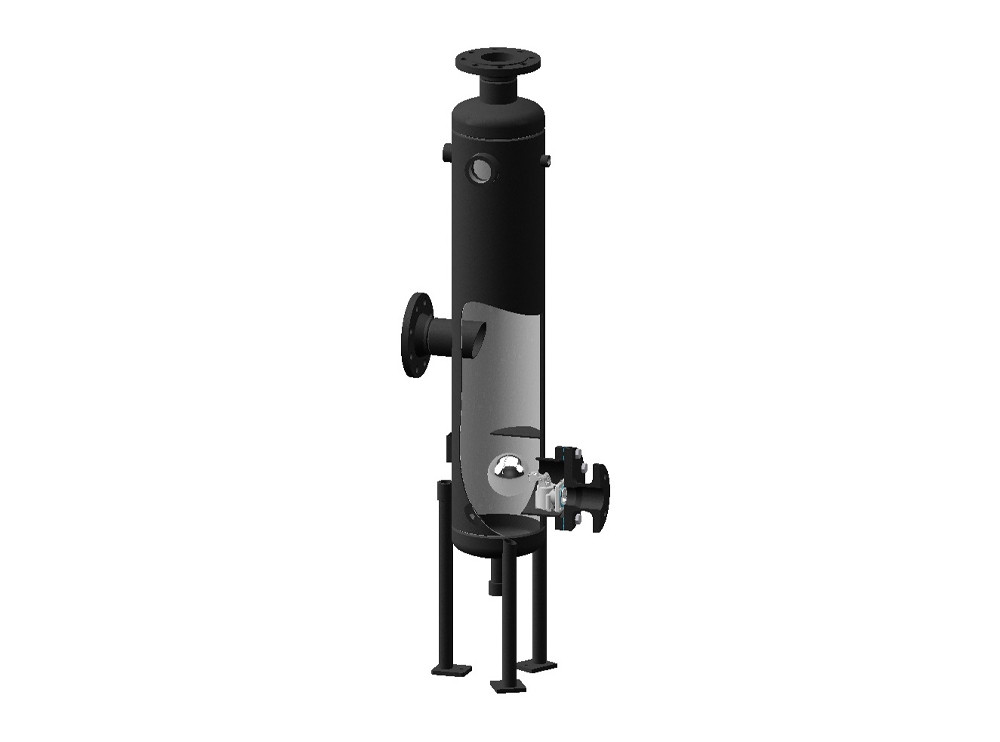

Function

For recovering flash steam from condensate,

The flash vessel allows the flash steam to separate from high pressure condensate. -

Use

High pressure condensate,

Boiler blowdown heat recovery systems -

Body material

RVST/S – carbon steel,

RVST/SS – stainless steel,

*Steam trap mechanism – Stainless steel -

Max. operating pressure

up to 13 bar for saturated steam

-

Max. operating temperature

for saturated steam: 250 ºC

-

Min. operating temperature

-10 ºC

-

Trap discharge capacity

Max.: up to 50000 kg/h,,

Min.: from 1800 kg/h -

Differential pressure on trap mechanism

Delta P: 4,5 , 10 and 12 bar

-

Installation

Horizontal condensate inlet and outlet.

-

Supports

Installation supporting feet floor,

Installation supports on body (without supporting feet). -

Non-standard design

available on request; custom flanges, made to order

-

Connections

Flanged EN 1092-1 PN 16,

Female threaded ISO 7 Rp (NPT on request),

Flanged ASME B16.5 Class 150 on request