Valsteam ADCA

Specyfikacje

-

Application

Saturated and superheated steam,

Hot and superheated water,

Thermal oil,

Air, gases and others -

Body material

Carbon steel A216 WCB & Stainless Steel D12 Trim

-

Max. operating pressure

Up to 13,3 bar (Body design PN16),

Up to 33,3 bar (Body design PN40), on request -

Flow rate coefficients

Kvs 10 to 100 (m³/h)

-

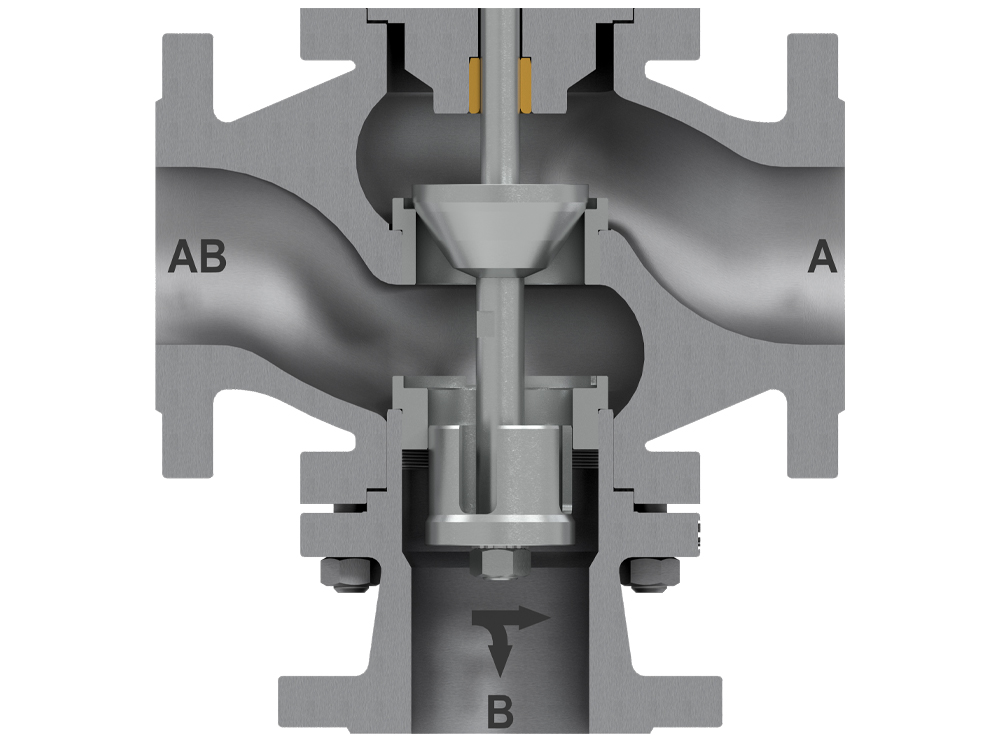

Type & Plug design

Three-way, desing with diverting plug

-

Stem sealing

PTFE/GR V-Rings – up to 220ºC (standard),

Graphite packing – up to 400ºC,

Stainless steel bellows – up to 400ºC (PMO: 25 bar) -

Valve sealing

Metal to metal (class IV), standard

-

Actuator

Pneumatic Actuator ADCATrol PA series

-

Actuator direction of action

Air to open (standard) / Air to close

-

Digital Electro-Pneumatic Valve Positioner

0-10V, 0-5V, 0-20mA or 4-20mA input

-

Connections

Flanged EN 1092-1 PN 16,

Flanged EN 1092-1 PN 40