Valsteam ADCA

Specifications

-

Application

Cold, hot and superheated water,

Oil,

non-toxic fluid with a min. specific gravity of 0,75 kg/dm³ -

Body material

Carbon steel

-

Max. operating pressure

30 bar

-

Max. operating temperature

EPDM valve sealing: 130 ºC,

FPM / Viton valve sealing: 200 ºC,

Metal to metal sealing: 250 ºC -

Flow rate capacity

Up to 746 NL/min,

Values shown refer to capacities of air discharge at 15 ºC, under average atmospheric pressure (1013 mbar) -

Differential pressure

Delta P max.: 30 bar,

Delta P min.: 0,5 bar -

Valve sealing

Metal to metal; EPDM; FPM / Viton

-

Outlet pipe connection

Female threaded ISO 228,

Female threaded NPT, on request -

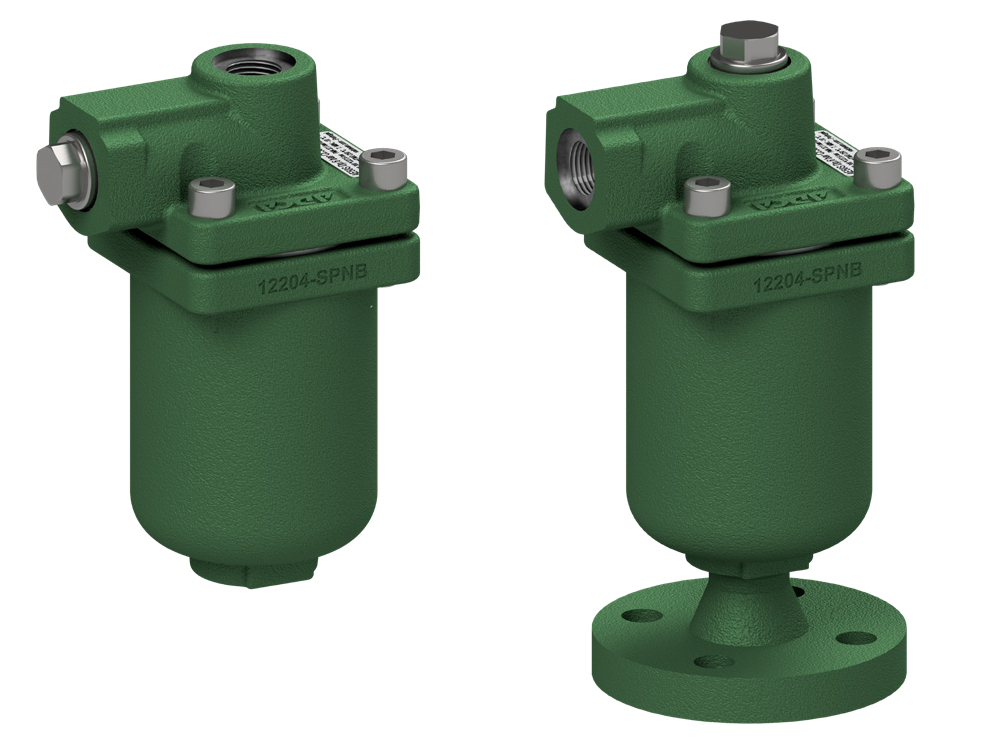

Inlet pipe connection

Female threaded ISO 7 Rp A,

Female threaded NPT, on request,

Flanged EN 1092-1 PN 40,

Flanged ASME B16.5 Class 150 or 300, on request