Automatic pump traps

Refine

- 10 products per page

- 25 products per page

- 50 products per page

- Relevance

- Created at

- Product code

- Name

- Available

-

Valsteam ADCA

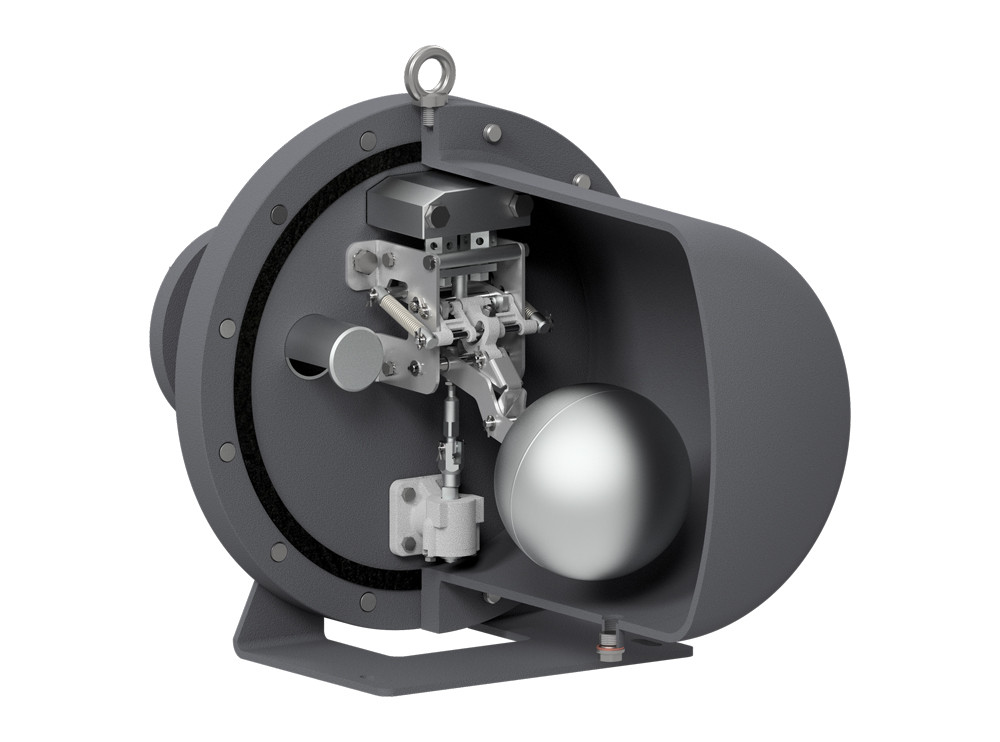

Product code: A.55.4870.000

ADCAMat® Automatic Pump Trap ADCA PPT14 (Mechanical Pump with Built-in Steam Trap & Check Valves)

-

Use

Drain and lift* steam condensate from heat exchangers, among others,

*Transfer, discharge, drain, filling, outlet, lifting -

Motive fluid (medium)

Saturated steam, compressed air, nitrogen and other gases

-

Pumped fluid (medium)

Steam condensate, diathermic oil, Diesel and petroleum products and other liquids compatible with the construction

-

Body material

Carbon steel – model PPT14S,

Stainless steel – model PPT14SS -

Motive inlet pressure

Max.: 10 bar,

Min.: 1 bar -

Fluid operating temperature

Max.: 185 °C,

Min.: 20 °C -

Trap discharge capacity

Max.: up to 10100 kg/h,

Min.: from 650 kg/h -

Pump discharge capacity

Max.: up to 1830 kg/h,

Min.: from 520 kg/h -

Pump discharge per cycle

11 (L) one volume for all dimension

-

Connections

Flanged EN 1092-1 PN 16,

Flanged ASME B16.5 Class 150, on request,

Female threaded ISO 7 Rp (threaded flanges), on request

Dimension:

1.1/2”x1”, 2”x1.1/2”; DN40x25, DN50x40Price according to configurationAvailable on requestMore about the product -

-

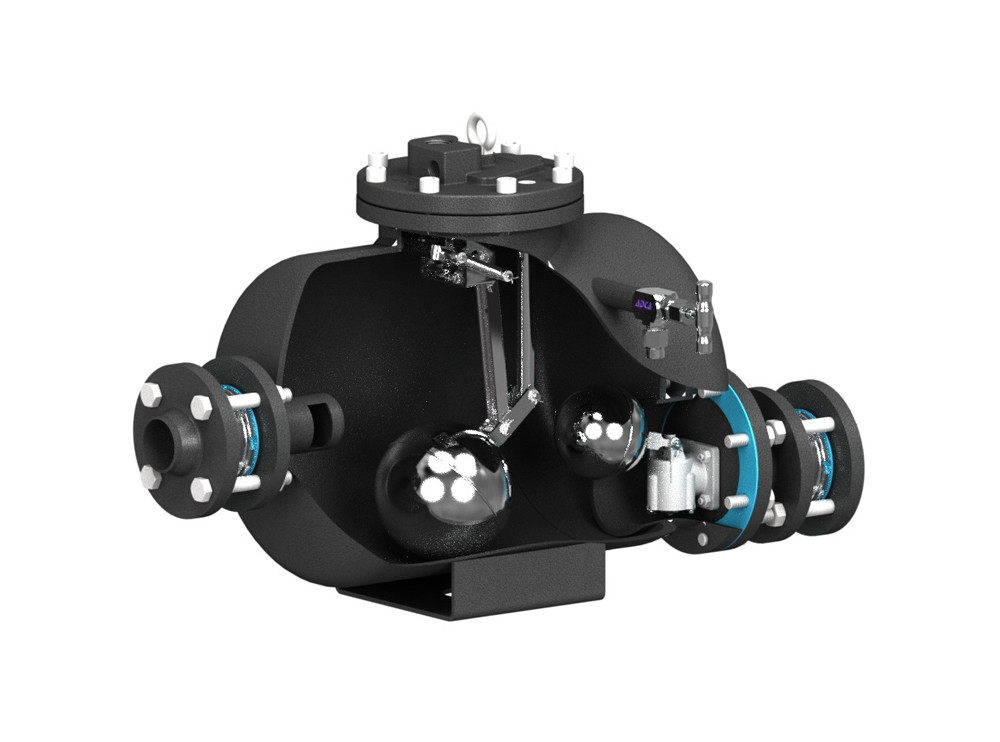

Valsteam ADCA

Product code: A.55.4880.000

ADCAMat® Automatic Pump Trap ADCA APST (Mechanical Pump with Built-in Steam Trap)

-

Use

Drain and lift* steam condensate from heat exchangers, among others,

*Transfer, discharge, drain, filling, outlet, lifting -

Motive fluid (medium)

Saturated steam, compressed air, nitrogen and other gases

-

Pumped fluid (medium)

Steam condensate, diathermic oil, Diesel and petroleum products and other liquids compatible with the construction

-

Body material

Carbon steel – model APSTS,

Stainless steel – model APSTSS -

Motive inlet pressure

Max.: 10 bar,

Min.: 1 bar -

Fluid operating temperature

Max.: 185 °C,

Min.: 20 °C -

Trap discharge capacity

Max.: up to 16000 kg/h,

Min.: from 1800 kg/h -

Pump discharge capacity

Max.: up to 4580 kg/h,

Min.: from 1850 kg/h -

Pump discharge per cycle

22 (L) one volume for all dimension

-

Connections

Flanged* EN 1092-1 PN 16,

Flanged* ASME B16.5 Class 150, on request,

Female threaded ISO 7 Rp (threaded flanges*), on request,

*Check valves and welding neck counter flanges included

Dimension:

2”x2”, 3”x2”; DN50x50, DN80x50Price according to configurationAvailable on requestMore about the product -

-

Valsteam ADCA

Product code: A.55.4882.000

ADCAMat® Automatic Pump Trap ADCA APST-HC – High Capacity (Mechanical Pump with Built-in Steam Trap)

-

Use

Drain and lift* steam condensate from heat exchangers, among others,

*Transfer, discharge, drain, filling, outlet, lifting -

Motive fluid (medium)

Saturated steam, compressed air, nitrogen and other gases

-

Pumped fluid (medium)

Steam condensate, diathermic oil, Diesel and petroleum products and other liquids compatible with the construction

-

Body material

Carbon steel – model APSTS-HC,

Stainless steel – model APSTSS-HC -

Motive inlet pressure

Max.: 10 bar,

Min.: 1 bar -

Fluid operating temperature

Max.: 185 °C,

Min.: 20 °C -

Trap discharge capacity

Max.: up to 30000 kg/h (High Capacity),

Min.: from 2400kg/h -

Pump discharge capacity

Max.: up to 4580 kg/h,

Min.: from 1850 kg/h -

Pump discharge per cycle

22 (L) one volume for all dimension

-

Connections

Flanged* EN 1092-1 PN 16,

Flanged* ASME B16.5 Class 150, on request,

Female threaded ISO 7 Rp (threaded flanges*), on request,

*Check valves and welding neck counter flanges included

Dimension:

2”x2”, 3”x2”; DN50x50, DN80x50Price according to configurationAvailable on requestMore about the product -